Representatives of the propane and fuel oil industries look at electrification policies in the real world.

To open the Industry Summit, Leslie Anderson, President & CEO of the Propane Gas Association of New England, and Roger Marran, President of Energy Kinetics, shared key developments and strategies as both the propane and fuel oil industries confront continued electrification incentives and broader regional decarbonization efforts.

Propane for the Long Run

Leslie Anderson of PGANE opened her presentation noting that the fuel oil and propane industries are more closely aligned than ever, and how the proposed resolution included policies that work for both industries. “We are fighting for the same thing.”

Her presentation focused on propane as “one of the good energies.” She explained that propane had a “story to tell,” noting that propane storage tanks and accessories – which are like a massive electric storage battery – are 100 percent recyclable, and that propane is non-toxic and hydrogen rich, has no ozone-depleting chemicals, has no methane, and its source energy is less than electricity.

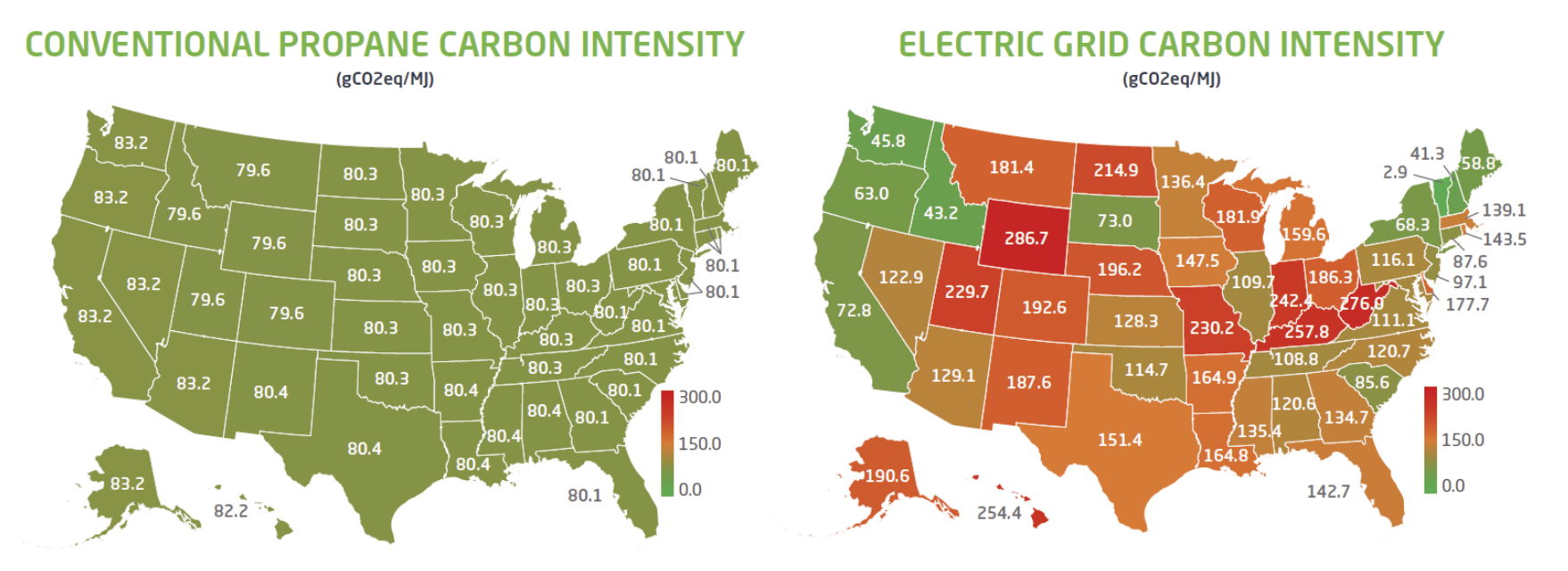

Anderson discussed how, when full fuel lifecycle analysis is considered, traditional propane has a much lower carbon intensity than the electric grid. These comments segued into the crux of her presentation: the future of renewable propane.

Renewable propane is a drop-in replacement for traditional propane, with the same chemical structure but produced from recyclable feedstocks and as a byproduct of renewable diesel production. Some exciting developments were the use of camelina as a feedstock. Camelina is a cover crop that provides additional income to farmers in their off-seasons, does not compete with food production, and has a very low carbon intensity. Anderson also revealed research into producing propane from recycled plastics as well as studies developing a process to convert carbon dioxide into propane, creating a negative carbon intensity.

Noting the growth of renewable propane; the prospect of a carbon neutral “propane cocktail;” conventional propane’s lower-carbon autogas for transportation; and the benefits of propane home energy for vulnerable populations in the U.S. and around the world, Anderson said, “We can get to net-zero faster than they can get to a net-zero grid. We have a plan to get there. We want a seat at the table.”

Anderson concluded by noting that many vulnerable populations in New England, especially those in mobile homes, cannot be successfully converted to electric/heat pump systems, and could have safer, warmer homes with propane. She added that PGANE has been collaborating with the AARP to address the issues of elderly homeowners (and others) who have installed heat pumps and now have piles of firewood in front of their homes to use for auxiliary heat, and how they would have produced fewer emissions if those homes had kept their propane or oil systems as backup heating sources.

Renewable Fuels and Energy Efficiency = Net Zero Now

Roger Maran of Energy Kinetics began his presentation reviewing the many initiatives of the prior administration that have been reversed, paused, or modified in the past year, remarking that over the years, “this industry has had more ‘Dewey Defeats Truman’ moments than anyone can imagine.” He credited the passion and persistence of the Legends and Jack Sullivan honorees, the Summit attendees, and “the people moving us forward” who continue to strive to make sure the industry has a pathway to the future.

Maran briefly reviewed the efforts of NORA’s Bob O’Brien and others working with the International Energy Conservation Code (IECC) to have Oilheat and renewable liquid fuel fired boilers and furnaces pass through the sub-committee and consensus committees. He noted that the industry’s representatives were working diligently, despite the pro-electrification fallacies in the IECC’s scoring methods and its insistence in considering site-energy only and thus ignoring metrics such as full fuel cycles, cross class comparisons, source energy, conversion losses, and transmission and distribution energy losses.

He then posed the following questions: “What are some options to cut GHG emissions in cold climate oil heated homes? How do various solutions compare in affordability, accessibility, and scalability?” The answers, naturally, followed.

Option 1: Biodiesel and Renewable Diesel: According to Maran, these renewable and sustainable energy sources offer an even higher achievement than GHG emission reductions alone. While life cycle analysis of GHG reductions is dependent on feedstocks and other factors, a 75 percent reduction is typically assumed for analysis purposes. These blends are a cost-effective pathway to reducing GHG emissions in oil-heated homes. State mandated blend increases in heating fuels could have a larger impact right now compared to years of infrastructure upgrades, and B100 boilers and furnaces are “future proof” as they are compatible with ever-increasing blend levels.

Option 2: Energy Efficiency: A recent NORA report reveals the outsized role energy efficiency plays in reducing GHG emissions. “A 25 percent savings is a 25 percent emissions reduction” he added. Furthermore, combining an equipment upgrade with 25 percent savings with B100 biofuels cost-effectively delivers 82 percent GHG reductions. Maran added that in this option, installing heat pumps or minisplits to update air conditioning systems can provide the homeowner with additional energy savings.

Option 3: Hybrid Systems: Calling this the “best of both worlds,” Maran extolled the benefits of having a heat pump and boiler or furnace work together. Rather than forcing homeowners into an “all or nothing” decision, a hybrid system ensures that there is always a backup heating option. Winter system repairs are no longer emergencies, and the homeowner can “vote with their fingers” to choose heating oil/Bioheat® fuel or electric heat depending on fuel prices and emissions. Maran noted that $0.30 kWh is equal to approximately $12 per gallon electric resistance equivalent. This option can easily adapt in a volatile energy market. While heat pumps can cut gallons by 50 percent, homeowners make their own determination about the energy source to use at any time, and the majority drop out of heat pump use when the outdoor temperatures drop to between 40° F and 30° F.

After reviewing additional statistics regarding heat pump water heaters and backup power options in power outages, Maran turned to the options available to consumers who “want it all today” – a net-zero carbon home that is affordable and comfortable in cold climates. Using today’s technologies, Maran considered the options to delivering 78.26 mmBTU/year heating and 5,995 kWh/year non-heating electric load to a home on Long Island, New York.

He made quick work of several options:

Option D: Offshore wind platform, turbine, transmission, and heat pumps: this option will cost approximately $85,000-$200,000 per home. Furthermore, he noted, offshore wind quality, cost, pace, and scale are not currently adding up to success.

Option C: Deep energy retrofit (passive house standard): this has an estimated cost of between $150,000-$200,000, or approximately 30 percent of the home’s value. The upside is that the homeowner would have virtually no heating or cooling costs once complete.

Option B: Whole house heat pumps and solar photovoltaics: estimated cost $50,000-$75,000 per home. Excess electricity may be generated during the off-season, but, Maran reminded the assembly, “the grid is not a battery,” and any excess would not be stored for later use.

Option A: NORA’s Net-Zero Carbon Home: “today’s ultimate solution to cut GHG cost effectively and quickly,” according to Maran, with a cost of approximately $12,000 per home. Using B100 biodiesel for heat and solar for electric power, the solar offsets any remaining carbon emission equivalents.

Maran then took a deeper look into heat pump technology, the impacts of anti-combustion policies, and, as Anderson had also noted, the real-world problem of people feeling cold when using heat pumps. According to the Department of Energy’s Cold Climate Heat Pump Challenge, supply air from heat pumps rarely exceeded 100° F, and was often around 80° F. With the air blowing from minisplit vents at or below skin temperature, it will feel cold, especially to the elderly. Or, as one installer reportedly said, “If you’re old, you’re cold!”

Maran concluded by suggesting that heating companies should add messaging to their invoices and statements that would “plant the seed” that heat pumps are expensive to run and the fuel industry has better solutions.