All

Impact on Service by Biodiesel Blends in Heating Oil

NORA has found that the transition to higher blends of biodiesel can occur with low costs and little impact on the consumer.

The National Oilheat Research Alliance (NORA) has conducted periodic surveys to assess the impact and role that biofuels play in the marketplace. Many view low-carbon fuels as the best path for the industry as it is reduces its environmental impact. Biodiesel is a low-carbon fuel that is available in most markets, is used widely and offers significant reduction of the amount of carbon dioxide released by heating appliances.

NORA has conducted ongoing research in this area and has found that the transition to higher blends of biodiesel can occur with low costs and little impact on the consumer. A number of retailers have been selling the higher blends of biodiesel.

To verify/validate the lab conclusions on biodiesel, NORA conducted a wide-ranging survey of retailers and service personnel. This latest survey, completed in December 2019 is summarized here.

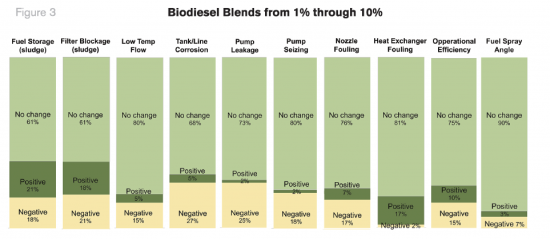

NORA received 207 responses to the survey with 107 of those responses indicating that they sold biodiesel (Figure 1). The parties not selling biodiesel indicated their unwillingness/inability to sell was focused on the availability of the fuel and potential service concerns.

To understand the relative impacts of various blends of biodiesel, NORA asked for responses based upon three biodiesel blending groups: B1-B10, B11-B25 and B26-B90.

The B1-B10 group essentially captures the category of fuel flowing into the market without disclosure. The second group, B11-25, captures parties who are actively blending, and are largely staying within manufacturer recommendations or ASTM listings. The third group, B26-90, are aggressive blenders of the fuel who have taken significant steps in their operation to blend at high levels.

Figure 2 shows the reported number of customers delivered to by each responding group.

NORA then asked a series of questions to identify maintenance issues related to:

- Fuel storage issues

- Filter blockage

- Low temperature flow

- Tank or fuel line corrosion

- Pump leakage

- Pump seizing

- Nozzle fouling

- Heat exchanger fouling

- Operational efficiency

- Fuel Spray Angle

B1-B10

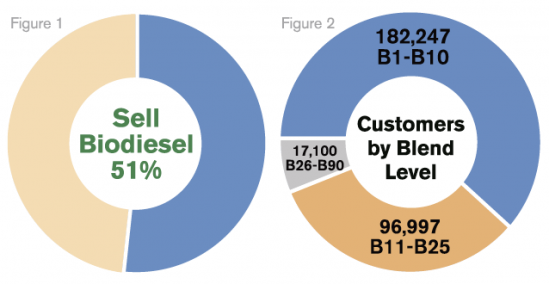

Figure 3 shows the responses of the low blenders, those blending B1-B10. These respondents indicated they are selling the fuel to more than 182,000 customers. The goal of the questions was to assess whether, in the opinion of the respondent, the addition of biodiesel affected service needs. The light green shading indicates that the respondent did not see the addition of biodiesel as affecting performance and this response is dominant. The most significant no change categories were: low temperature flow, heat exchanger fouling and angle of the fuel spray. Respondents indicated that the addition of biodiesel had a significant positive impact on fuel storage (sludge), filter blockage (sludge) and heat exchanger fouling. The two primary categories indicating concerns with biodiesel related to tank/line corrosion and pump seizing.

It should be noted that several respondents in this group identified as being compelled to use biodiesel as it was included in the fuel they purchased. Thus, some negative responses may reflect companies using the fuel involuntarily.

B11-B25

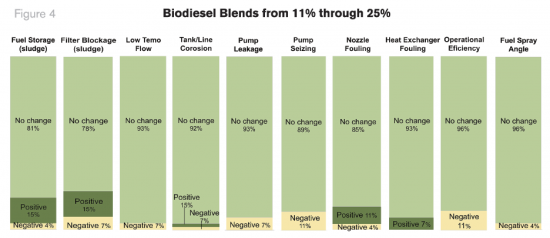

The next group were moderate users of biodiesel, B11-B25 (Figure 4). This category was established to evaluate marketers who are actively using the fuel but are doing it within the guidelines of the fuel which has been specified by ASTM. These respondents indicated they are selling the fuel to approximately 100,000 customers. This does not identify all customers as several respondents indicated “all” their customers were receiving the fuel but did not provide numeric values. Most of these customers had been receiving the high bio-blends for several years. Sixteen respondents indicated they had been selling those blends for over five years.

This category overall had higher overall positive remarks on service than the lower blend category. Contrary to the smaller blend level group, this group is committed to the fuel. Again, no change in service issues was the leading response. Six of the categories — low temperature flow, tank and line corrosion, heat exchanger fouling, operational efficiency and fuel spray angle — all were above a 90 percent positive rating.

Like the lower blend levels, 15 percent of respondents indicated that fuel storage and filter blockage were positively affected by the change. Operational efficiency and pump seizing had the highest negative response at 11 percent.

B26-B90

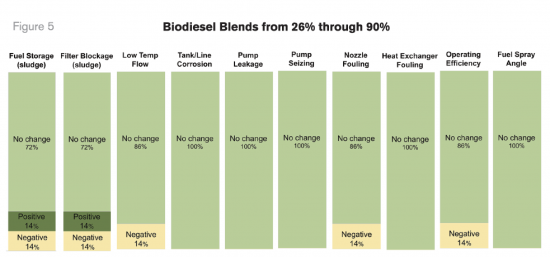

This final group (Figure 5) is retailers who have opted to sell a low-carbon fuel and implement unique strategies to sell, distribute and maintain equipment with high biodiesel content. Seven companies responded that they sold fuel at these

percentages with the distribution ranging from one year to over ten years. Through this sample, approximately 17,000 customers have been receiving these fuel blends.

In this group, five of the categories — tank line corrosion, pump leakage, pump seizing, heat exchanger fouling and spray angle — were all described as having no change. For fuel storage and filter blockage, one respondent indicated they had a positive impact and one indicated a negative impact. Similarly, one respondent indicated that service for low temperature flow, nozzle fouling and operating efficiency were negatively impacted.

Summary

Two primary areas of concern that have been raised with biodiesel are pump seizing and corrosion. The results of this survey do not clearly support this. Low blend users indicate more of a concern with these than higher blend users.

NORA has invested significant research time analyzing seized pumps recovered from the field as well as attempting to replicate pump seizing in the lab by running degraded biofuel and heating oil through them.

NORA’s analysis indicates that degraded polymers are causing the pumps to stick. However, NORA has heated and aged fuel but has failed to make the polymer that causes the sticking pumps. NORA has also been unable to determine whether the degraded polymers originate with biodiesel or petroleum oil.

At this time, NORA’s operating hypothesis is that the polymers are derived from inadequately filtered fuel. As a responsive measure, NORA is now evaluating the effectiveness of dual filtration.

Corrosion has also been identified as important. A major report funded by fuel and diesel engine manufacturers is currently in process and expected to be released in the fall of 2020. However, it has already been delayed multiple times.

Corrosion is very complicated but the key source of corrosion is related to the amount of water that the fuel holds, picks up or releases to the tank. Ultra-low sulfur diesel has also been identified as a potential for causing corrosion. However, regardless of fuel, the key indicator of corrosion problems is free-water. Therefore, while the studies continue, greater emphasis on water removal and prevention are strongly recommended.

NORA was authorized by Congress in 2000 to generate funding allowing the Oilheating industry to provide more efficient and more reliable heat and hot water to American consumers. NORA’s efforts focus on Consumer Education, Professional Education, Energy Efficiency & Safety and Research. For more information on NORA, go to NORAweb.org.

Related Posts

Why Quality Matters in Your Biofuel Blends

Why Quality Matters in Your Biofuel Blends

Posted on June 25, 2025

Incorporating Higher Blends of Biofuels

Incorporating Higher Blends of Biofuels

Posted on May 14, 2025

NORA Programs at Eastern Energy Expo

NORA Programs at Eastern Energy Expo

Posted on May 13, 2025

March Short-Term Energy Outlook

March Short-Term Energy Outlook

Posted on April 28, 2025

Enter your email to receive important news and article updates.