A futurist is defined as one who studies and predicts the future on the basis of current trends. When examining trends in home heating technology, certain concepts, like biofuels, condensing equipment, heat pumps and smart controls, immediately jump out. Follow the implications of these innovations, from how they exist in their current forms to their logical extremes, and you begin to develop a picture, however blurry, of what tomorrow’s heating technology might look like.

The National Oilheat Research Alliance’s Research & Development arm is charged with bringing that picture into focus by making the conceptual real. Collaborating with industry-leading manufacturers like Energy Kinetics and Babington Technology, NORA’s R&D team, led by Dr. Tom Butcher, works to turn concepts into projects, projects into prototypes, and prototypes into products that deliver real consumer value.

Several of the organization’s recent accomplishments were on display at the 2017 NEFI EXPO as Dr. Butcher, Energy Kinetics President and NORA board member Roger Marran, and NORA President John Huber brought the organization’s technological breakthroughs from the laboratory to the trade show floor. However, many more of NORA’s achievements are already on display every day, in the homes of Oilheat consumers across the U.S., as much of today’s energy-efficient, emissions-reducing heating technology owes itself to the tireless efforts of the Alliance.

With this in mind, the techs who service and install home heating systems, and the reps who market and promote them, owe it to themselves to take a closer look at some of the technological innovations coming down the pike.

A Look Back to Look Forward

The futurist’s predictions are rooted in current trends, but to understand those it pays to know how they developed in the first place. Many of the projects ongoing at NORA today are rooted in an agenda that was first established at a two-day Research Planning Meeting at Brookhaven National Laboratory, on Long Island, back in June 2014. (Oil & Energy was there – read “NORA Develops Research Agenda” for our coverage.) Priorities identified by breakout groups at that meeting include:

- A burner suitable for any bioblend up to B100

- Modulating burners

- Tankless coil cost analysis for options to improve efficiency

- Dilution venting system for near condensing or fully condensing equipment

- Low-cost near condensing boilers

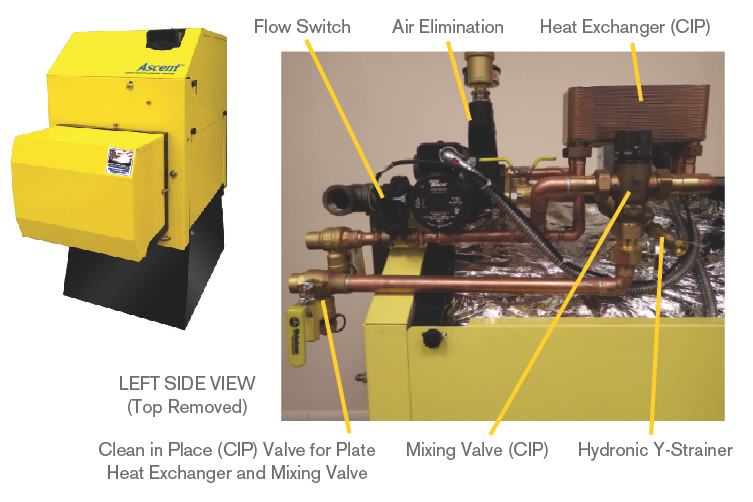

Ascent™ Combi Boiler

The Ascent™ Combi Boiler by Energy Kinetics is a high-efficiency space- and water-heating system developed in response to some of the most common complaints consumers make about oil-fired tankless coil boilers, that they’re inefficient, loud and don’t provide enough hot water. Recognizing that these impressions were at their core product-based rather than fuel-based, Energy Kinetics sought to develop an alternative to tankless coil boilers that could provide better quality hot water at higher efficiency and with quieter operations.

To that end, the Ascent™ development team established the following criteria for system design:

- Competitive price

- Drop-in replacement for tankless coil

- Much higher efficiency with lower idle loss

- Better hot water temperature and comfort

- Long life pressure vessel

- Hard water serviceability

- No tankless coil flange studs

- Option to automatically adapt to hot water schedule.

After months of hard work, the end result is a combination space- and water-heating system that can achieve an annual fuel utilization efficiency (AFUE) of up to 87% while burning oil at .85 to 1.25 gallons per hour (GPH). Capable of replacing up to four section boilers, the American-made Ascent hits a consumer-friendly price point, with an add-on option to include a silent burner cover.

When asked about the R&D project, Marran stated: “The Ascent Combi was a fun product to develop, because there are so many opportunities to improve over tankless coil boilers. We’ve demonstrated it to hundreds of heating professionals, and the response has been amazing. We at Energy Kinetics are as excited as they are. The Ascent is a perfect addition to our System 2000 family of products to give heating professionals more options that homeowners will love.”

In terms of hot water output, the system can produce nearly four gallons per minute (GPM) and be set to any of four simple operating modes: plate warming mode, for always-ready instantaneous hot water; on-demand mode, for hot water within two minutes of cold start; and two smart learning modes that match daily usage patterns for preferred water temperatures with no delay.

The Ascent Combi Boiler was premiered at the 2017 AREE Convention and 2017 NEFI EXPO and is slated to be available for purchase in mid-August.

Babington Self-Modulating Multi-Fuel Oil Burner

Currently in development and testing stages is the FlexFire Smart Burner by Babington Technology. An alternative to conventional high-pressure burners, the FlexFire deploys a unique low-pressure air atomization technology combined with power electronics to create a self-modulating, multi-fuel burner capable of enhancing the efficiency of traditional oil-fired equipment and enabling biodiesel use within the same burner platform.

Babington’s design goal from the outset was to leverage its signature clean-burning, low-variable firing rate capability with low-cost electronics to create something entirely new. The unique approach allows for a dynamic firing rate control, empowering virtually any oil-fired appliance to operate with the efficiency and flexibility of a natural gas system, burning between 0.2 and 0.75 gallons per hour while consuming less than 60 watts of power and using any liquid fuel blend. The low-energy Babington atomization system makes this all possible. It turns the nozzle inside out and creates a fine spray, atomizing any liquid fuel into submicrons.

Whereas conventional burners control their heat output by cycling on and off at some prescribed duty cycle, the FlexFire will dynamically adjust its firing rate multiple times per second, in real time. This will result in much tighter temperature control, minimal overshoot and a significant reduction in motor stop-and-start, thus minimizing long-term wear.

Key features include:

- Precision heat control across the load range of a select boiler or warm air furnace

- Plug and play compatibility, allowing a particular brand of equipment to be calibrated and pre-programmed for optimum performance

- Condensing applications

- Multi-fuel compatibility with biodiesel blends of B20, B50 and B100

- Smart control for overall energy efficiency

- Self-tuning for easy diagnostics.

Also in the pike for Babington is the B50 Compatible Self-Modulating Boiler, which is being developed through a joint agreement with Energy Kinetics. The two manufacturers have committed to developing three self-modulating prototype boilers, initial field trials for which are expected to begin this winter. “Babington is extremely excited about working with innovative leaders like Energy Kinetics in cooperation with the National Oilheat Research Alliance,” said Andrew D. Babington, President, Babington Technology. “Our long-term goal is to introduce to the market a next-generation burner that can not only optimize energy-efficiency in the home, but reduce total ownership cost while enabling biodiesel-compatible heating systems to better compete with natural gas and propane — and help reduce the carbon footprint,” adds Babington.

Dilution Air Venting

A third R&D project showcased by Marran at NEFI EXPO centered on a new method of boiler venting co-sponsored by NORA and the New York State Energy Research & Development Authority (NYSERDA). Dilution air venting, referred to as “a page out of the water heater playbook,” seeks to address several challenges of venting today’s high-efficiency and condensing boilers, including:

- Low stack temperatures (<250ºF) are not suitable for natural draft in chimneys.

- Condensing flue gas with sulfur aggravates long-term serviceability and performance.

- PVC is not code compliant for boiler venting in New York City and New Hampshire.

In a polypropylene-made dilution air vent, flue gas would enter the vent chamber where it would mix with dilution air before exiting as a lower-temperature and “dryer” mixed flue gas. Marran stated, “Dilution air venting is a proven technology, and its application in Oilheat boilers enables non-condensing equipment to run at higher efficiency. If a chimney needs a new liner, polypropylene is much more cost effective and easier to install than stainless steel, reducing overall installation costs and bringing higher efficiency into reach for many more homes.”

The dilution vent would help today’s oil-fired boilers achieve real efficiency gains by eliminating an energy-wasting draft regulator, providing sealed combustion isolated from the building envelope, and by reducing stack temperature for higher steady state efficiency. By incorporating proven components and off-the-shelf solutions, it could serve a wide range of applications, including clean light off and burner operation, robust high and low draft operation, and cold and warm temperature, as well as low and high wind and humidity operation.

With the right setup in place, dilution air venting might prove effective in some of the most extreme cold-weather climates. Hammering this point home, field results from tests conducted in Fairbanks, Alaska, using a combination hood and stainless steel nozzle demonstrated no problems with dilution air venting in the Energy Kinetics 90+ Resolute heat and hot water system, even at sustained temperatures as low as -60ºF.

As an organization with “research” in both its name and founding charter, NORA continues to push the innovation envelope for oil-fueled home heating. For those industry stakeholders looking to learn more or contribute their own knowledge and ideas, the Alliance will hold its next Technical Workshop in coordination with the Southern New England Energy Conference (SNEEC) at Gurney’s Resort in Newport, RI, September 18-19. Presentation proposals are now being accepted. Abstracts should be emailed to TButcher [at] NORAWeb [dot] org or faxed to 571-234-7756.