All

A Follow-Up Examination

Flaws in the U.S. Department of Energy’s standard annual fuel utilization efficiency (AFUE) rating system are well documented. In fact, Oil & Energy recently dredged up from our archives a 2006 (!) article on the topic, which somewhat exhaustively breaks down how the efficiency metric designed for furnaces misses the mark on boiler efficiency.

Among the AFUE rating’s many failings are these: it omits boiler standby losses, which occur after a thermostat call is satisfied, especially for boilers that are poorly insulated or that maintain temperature; it doesn’t adequately account for the high thermal mass and large water content of many boiler models; it ignores jacket losses; and it does not apply to heat and hot water systems. For these reasons, the standard grossly underrepresents the energy savings possible with those heavily insulated boiler models designed for enhanced energy recovery, especially the ones that also provide hot water. The list goes on, but those are the basics.

The AFUE rating system has never been fine-tuned to boiler specs, yet today it remains the DOE’s standard efficiency rating for both boilers and furnaces. DOE is currently considering and expected to switch to a new “AFUE2” rating for furnaces, but boiler efficiency will continue to be (mis)represented as AFUE. In accordance with federal regulations, as of January 15, 2021, the minimum AFUE for newly manufactured oil-fired water boilers increases to 86 from the previous minimum of 84, and the minimum AFUE for newly manufactured oil-fired steam boilers increases to 85 from 82.

In the meantime, pressure is mounting to drastically reduce fossil fuel emissions and improve buildings’ heating and cooling efficiencies. As a result, policymakers are increasingly calling for conversions to electric heat pumps – systems whose efficiencies are measured in terms of heating seasonal performance factor (HSPF) and seasonal energy efficiency ratio (SEER), not AFUE.

With all of this playing out simultaneously, Oil & Energy decided it was time to take a second look at boiler efficiency, and who better to help than Energy Kinetics CEO Roger Marran. The main source for the aforementioned 2006 article, Marran recently presented on efficiency standards and several other topics at the NORA Technical Review and Research Planning Workshop held April 3-4 in Plainview, NY. Oil & Energy caught up with Marran shortly thereafter to discuss the efficiency picture as he sees it today in the greater context of ongoing debates regarding electrification and heat pump conversions.

EnergyGuide Misreads Efficiencies & Costs

“HSPF is not easily correlated to boiler or furnace efficiency,” Marran says. That’s easy enough to see — with heat pump HSPFs typically in the single digits and boiler/furnace AFUEs in the 80s and 90s — but it takes some technical understanding to grasp why this is and why it matters to the larger discussion about efficiency standards for different energy sources.

The DOE EnergyGuide (the efficiency label that shows consumers AFUE for boilers and furnaces and HSPF and SEER for heat pumps) assumes that 1 kilowatt hour (kWh) of electricity produces 3,412 British thermal units (Btu) of heat energy, and 1 gallon of heating oil produces 137,500 Btu; therefore, assuming a nationwide average electricity cost of $0.132 per kWh in December 2018 and nationwide average heating oil cost of $2.86 per gallon in December 2018, electric heating cost the average consumer $38.83 per million Btu when heating oil costs the average consumer $20.80 per million Btus.

Generally speaking, air source heat pumps can “pump” 3 kWh of heating energy for every 1 kWh of electricity used, for a Coefficient of Performance (COP) of 3. Although it is possible to achieve 300% efficiency by “moving” heat, field studies indicate that this high benchmark is not achieved in most oilheat states in winter months. In calculating energy ratings, DOE assumes the COP of a heat pump is equal to the HSPF divided by 3.412 (because 1 kWh produces 3,412 Btus). However, as Marran points out, “COP and heat pump output generally drop as the outdoor temperature drops.” And while some heat pumps may seem to maintain an output that is somewhat comparable in warm and cold outdoor temperatures, it appears that these models simply reduce the output at warm temperatures to give this impression.

According to a study on “Field Performance of Inverter-Driven Heat Pumps in Cold Climates” published by the DOE, heat pumps’ winter COP ranges from 1.4 to 2.4. Furthermore, electricity prices are much higher in New England than elsewhere in the country. According to the U.S. Energy Information Administration (EIA), the average cost of electricity in New England for December 2018 was $0.21 per kWh.

If you do the math using the Btu content above, paying $0.21 per kWh to heat a New England home with electricity would be like paying $8.46 for a single gallon of heating oil. Factor in the winter COP of 1.4 to 2.4, and running an electric heat pump in New England this past December cost the equivalent of $3.53 to $6.04 per gallon of heating oil.

The actual average cost of one gallon of heating oil in New England in December 2018: $3.14. (And adjusting for a non-AFUE-based real boiler efficiency of 85%, it cost the equivalent of $3.69 per gallon, still significantly lower than the heat pump price-per-gallon equivalent in most cases.)

Of course, none of this is apparent from the AFUE or HSPF rating the consumer sees when shopping for new heating appliances. “If you look at an EnergyGuide sticker or the Energy Star website, people assume heat pumps will be installed with a certain load, and they have standards for how they calculate that,” Marran says. “Somebody may look at the Energy Star site and see annual and lifetime costs and say, ‘That’s great, I pay a lot more than that for oil,’ but what they don’t see is that their boiler has about six to ten times the heating capacity of a heat pump and more than double the lifespan (25 years versus just 12 for a heat pump). Plus, the heat pump operating costs Energy Star lists are not at all reflective of cold climates, as electricity prices are listed at $0.109 per kWh and heating demand calculations seem to be for a climate similar to Virginia.”

This gets at the heart of the issue: DOE’s efficiency ratings for heat pumps and boilers are both fundamentally flawed in their own right. When policymakers then try to compare these inaccurate efficiency representations, they end up compounding the inaccuracies. “It’s a missed opportunity for consumers and policymakers to make more informed decisions for better outcomes,” Marran says.

A Good Idea But 2 Little 2 Late

As mentioned earlier, furnaces are expected to soon adopt the AFUE2 rating, which accounts for furnace fuel and fan power, as well as standby and off-mode power consumption. The measured value represents the sum of usable heat and fan benefit, divided by the total amount of fuel and electricity consumed. The thinking behind shifting from AFUE to AFUE2 is that it is easier for consumers to understand one simple metric than the three separate standards currently in place for furnaces.

If only such thinking carried over across the board for all heating systems. Instead, while furnaces move from AFUE to AFUE2, heat pumps are scheduled to move from SEER and HSPF to SEER2 and HSPF2, starting January 1, 2023. According to DOE, “these amendments address off-mode test procedures, test set-up and fan delays, (blower) pressure conditions for testing, represented values for [heat pumps with multiple refrigerants], the methodology for testing and calculating heating performance, and testing of variable speed systems.”

Again, this might make heat pumps’ standard efficiency ratings better representative of these devices’ actual energy efficiency, but it says nothing about how those systems compare with other types of heating appliances or other energy sources.

“The industry would be viewed in a more positive light by having a much more accurate rating system that demonstrated real savings potential; and even more so in today’s climate if boilers, furnaces, heat pumps, and water heaters were more easily compared for operating and lifetime costs,” Marran argues. “This is heavily impacted by the rating standard, fuel costs used in EnergyGuide labeling, and distribution efficiency (duct losses).”

As far back as 2010, DOE stated its intention to include some information about full fuel-cycle efficiency or source fuel efficiency in its ratings guides, which would have empowered consumers to make better decisions about the fuels and equipment they choose to heat their homes. Nine years later, crickets. Meanwhile, the deliverable fuels industry continues to come under attack despite advances being made with cleaner fuel blends and more efficient heating equipment.

Succeeding Despite Standards

To their credit, Marran and his team at Energy Kinetics are less concerned with reforming boiler efficiency standards than with continuing to improve their products’ performance and real efficiency. As a result, Energy Kinetics continues to raise the bar not only for oil-fired boilers, but also for home heating systems in general. And as a nice side effect of these efforts, Energy Kinetics systems are able to achieve AFUE ratings well above 90, making them some of the highest-rated oil-fired boilers available today.

“We have been able to achieve higher efficiency through boiler design, primarily by extending our flue pass surface area by 60% to improve combustion efficiency,” Marran says. Because AFUE is more representative of ‘peak’ efficiency, lower idle loss results in a tightening between a system’s real efficiency and its AFUE rating. “This means that the annual heat and hot water efficiency for the Resolute™ RT with thermal purge is only a few points below the 91.3 AFUE rating,” Marran explains. “For comparison, many other boilers have hot burner doors, tankless coils, and poor insulation, and the annual efficiency can be nearly 40% lower than indicated by AFUE.”

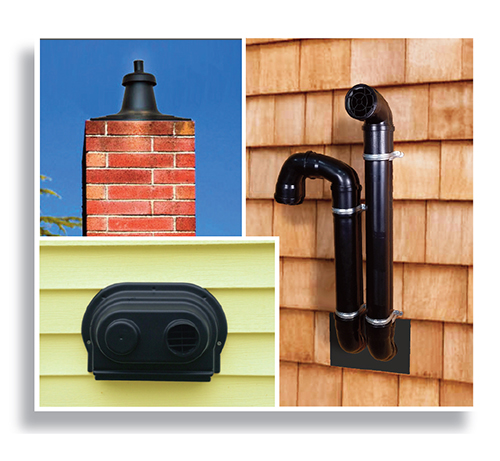

Marran continues: “Systems achieving over 90 AFUE have a challenge and opportunity for venting. That’s because the stack temperature is not high enough to rely on natural draft or to vent using conventional chimney materials. Our oil-fired Resolute RT and Ascent Plus Combi boilers can be sidewall or chimney vented using polypropylene (plastic) vent piping. Centrotherm 3” corrugated flex piping can be run through a chimney as a chase. The cost of relining a chimney with a stainless steel liner alone may justify upgrading to one of these models.”

As for the new minimum AFUE ratings that go into effect for boilers in 2021, Marran has nothing to worry about. “All of our boilers continue to qualify,” he says. While he admits that puts Energy Kinetics “toward the high end versus other manufacturers,” he doubts there will be any shortage of products resulting from the change in standards. “But it does put pressure on the boiler industry, and the product mix in 2021 may look a little different than it does today because of it.”

Related Posts

From Blue Flame to Biofuels

From Blue Flame to Biofuels

Posted on June 25, 2025

HEAT Show Announces Fenway Park Backyard BBQ

HEAT Show Announces Fenway Park Backyard BBQ

Posted on May 15, 2025

Delivering New York City’s Clean Energy Solutions

Delivering New York City’s Clean Energy Solutions

Posted on May 14, 2025

Are You a Leader or a Boss? The Choice is Yours

Are You a Leader or a Boss? The Choice is Yours

Posted on May 14, 2025

Enter your email to receive important news and article updates.