All

The Best Way to Reduce Greenhouse Gas Emissions

by Michael Devine, President, NORA; Don Farrell, Communications Director, NORA

It was only five years ago when Arthur Marin, Executive Director of the Northeast States for Coordinated Air Use Management (NESCAUM) addressed the Oilheat Manufacturers Association about the States in the Northeast contemplating policies that would demand drastically reduced carbon emissions from the heating sector. In the years since, many policies have been put in place that require homes to be on a path to significant atmospheric carbon emission reductions.

First among the strategies to eliminate carbon is the removal of on-site combustion for heating and replace it with electric heat pumps. The thinking behind this is that heat pumps can eliminate carbon emissions quickly and completely once the grid is free of carbon-producing electric generation. Much debate has ensued on the efficacy of heat pumps in extremely cold weather, the concerns about the huge increased demand on the grid and the feasibility and speed achieving carbon-free electric generation, as well as the economic consequences of doing so.

The National Oilheat Research Alliance (NORA) decided to let good science show whether heat pumps or low-carbon liquid biodiesel is a better and faster reducer of carbon emissions. Thus was born the Green House Gas Calculator, a transparent multi-variable calculator to examine the conversion of existing oil-heated homes to electric heat pumps versus upgrading the liquid-fueled heating appliance while increasing the amount of biodiesel/renewable liquid fuel used by that appliance.

The calculator, developed for NORA by PriMedia, uses an Excel-based spreadsheet that allows the user to make key input changes to examine the results of different actions and approaches to reduce greenhouse gases. It also shows how macro activities in the background, such as the decarbonization of the electrical grid, impact the results. Additional factors may be added, either in conjunction with NORA or independently. Like most models, this was developed over time with input from many stakeholders. Good modeling practice has been the basis for this open-source Excel Calculator. To ensure the accuracy, the model was reviewed by EarthShift Global CEO & Founder Lise Laurin. Version 7.1 was deemed to “fairly and accurately present the impact of changes in variables.”

Connecticut Use-Case

To explain the GHG Calculator and its functions, along with the impact of different variables, this article will use a variety of inputs focused on a Connecticut use-case.

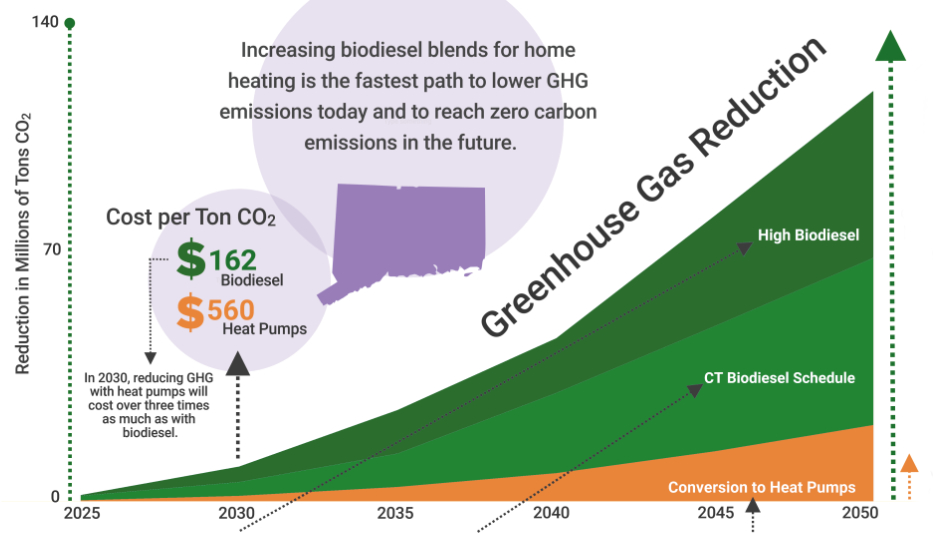

Figure 1 provides the result for the Connecticut use-case and shows the effects of converting all current oil-heated homes to no-carbon liquid solutions by 2050. This model uses normal 5% liquid fuel appliance upgrades per year versus all-electric (heat pump plus resistance backup) conversions at a rate of 1% per year. This graphic shows how the high use of biodiesel blending, along with normal appliance upgrades, reduce carbon emission considerably faster and at a much lower cost than does converting to electric heat pumps.

Connecticut has a biodiesel use mandate in place and its effect on carbon emissions can be seen by the lighter green color in Figure 1. In fact, the mandated levels produce carbon reductions more than three times greater than will heat pumps (orange). Additionally, if an ever-higher biodiesel blend scenario is implemented (darker green), the GHG savings are almost five times as great by 2050.

Of equal importance, the reduction using biodiesel comes at a much smaller cost. Using 2030 as a snapshot, the GHG reduction cost with heat pumps is more than three times greater than with the biodiesel.

Calculator Inputs

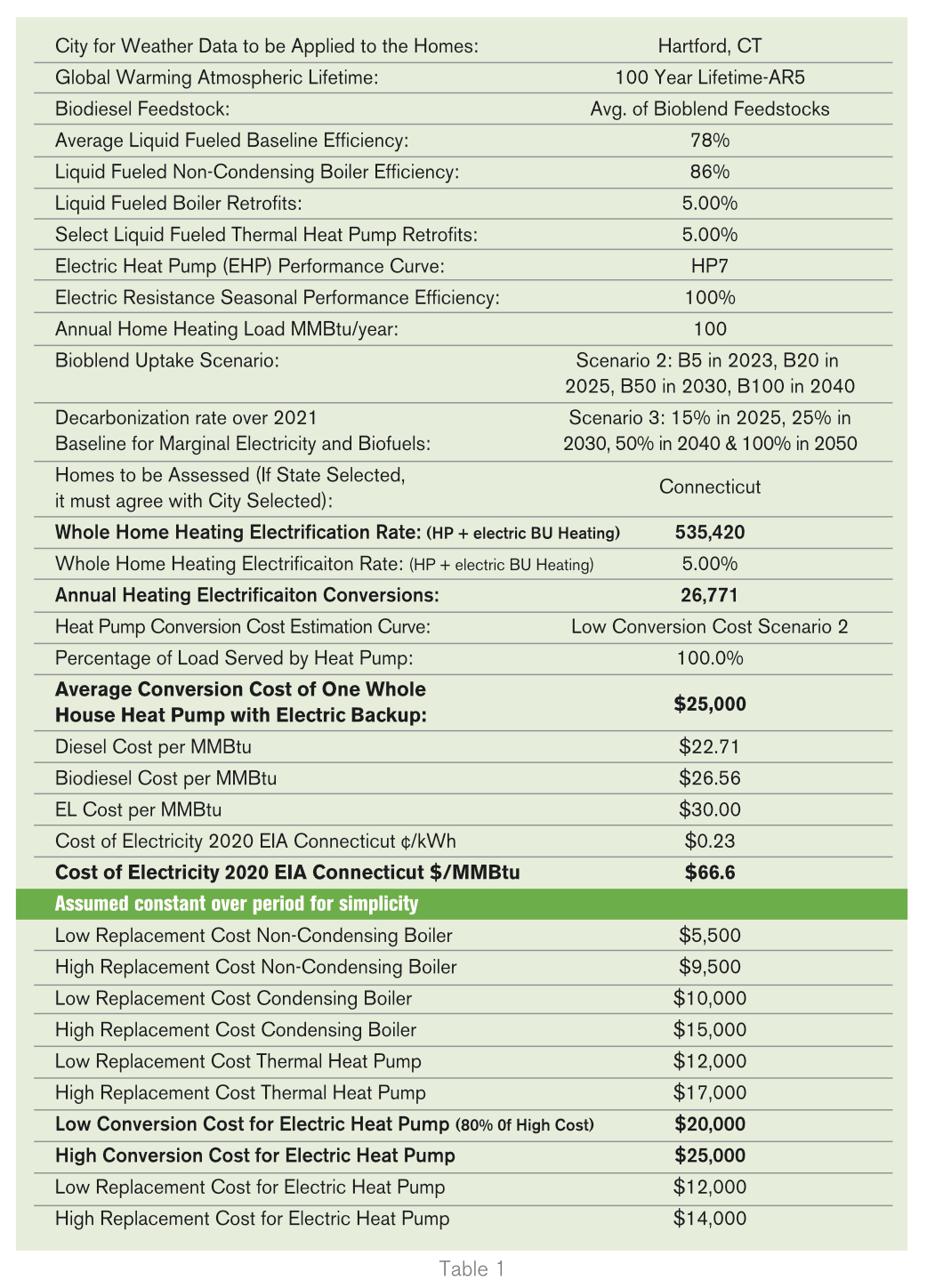

To ensure accuracy and flexibility, the GHG Calculator allows for more than 30 different inputs (Table 1). Among these are: location, global warming atmospheric lifetime, biodiesel feedstock, heating appliance efficiency, heat pump performance, heating load, biodiesel uptake scenarios, grid decarbonization rates and liquid fuel appliance and heat pump installation rates. The calculator allows additional inputs that include costs for both fuels and installation and conversion costs.

Using the GREET Model, the calculator assigns carbon emissions weight from both the liquid fuels and electricity. GREET stands for Greenhouse Gases, Regulated Emissions & Energy use in Technologies; it is a full life-cycle model sponsored by the Argonne National Laboratory at the U.S. Department of Energy’s Office of Energy Efficiency & Renewable Energy.

What Does it All Mean?

The final result for the Connecticut use-case scenario (Figure 1) in which converting all current oil-heated homes to no-carbon liquid solutions by 2050—and assumes normal 5% liquid fuel appliance upgrades per year versus all-electric (heat pump plus resistance backup) conversions at a rate of 1% per year—shows that high bio-blending along with normal liquid fuel appliance upgrades are more beneficial both in cost and rate of decarbonization to liquid-fueled homeowners and citizens in Connecticut.

Furthermore, looking at 2030, the cost to homeowner per ton of CO2e removed is $560 for heat pumps and $162 for high biodiesel blends. This means that in 2030, the cost to homeowners to remove the same amount of cumulative GHG is approximately 3.5 times higher with electrification of oil-heated homes. It should be noted that this analysis of costs did not assess or incorporate upstream costs associated with a major transformation of the electric distribution system, which will likely impact pricing of electricity.

In addition to Connecticut, the calculator has already been applied to Maine, Massachusetts, Rhode Island, New York and New Jersey with similar results and only variations based upon size of market, weather, prices and each State plan for biodiesel uptake.

The NORA GHG Calculator is the first proven, analytical look at the benefits of carbon reduction using biodiesel in home heating in comparison to electric heat pumps. In addition to the economic and environmental benefits, the liquid fuel heating industry is already positioned, and in fact has begun the transition. It is of added value that very few changes are needed to the delivery, storage and use of biodiesel blends, even at very high levels. Technical issues have been given the highest priority by the NORA, Clean Fuels Alliance America, and others. Heating appliance manufacturers are currently gearing up for full biodiesel use and liquid fuel retailers and wholesalers have made the commitment to continue to elevate the biodiesel blending as fast as possible.

Reducing and eventually virtually eliminating carbon from homes is the right thing to do and the liquid heating fuels industry is on the right track to do it.

NORA has applied the GHG calculator to Maine, Massachusetts, Rhode Island, New York, New Jersey and Pennsylvania. To see the results and more detailed explanations, reports and graphics for each State, go to NORAweb.org/ghg.

Related Posts

From Blue Flame to Biofuels

From Blue Flame to Biofuels

Posted on June 25, 2025

HEAT Show Announces Fenway Park Backyard BBQ

HEAT Show Announces Fenway Park Backyard BBQ

Posted on May 15, 2025

Delivering New York City’s Clean Energy Solutions

Delivering New York City’s Clean Energy Solutions

Posted on May 14, 2025

Are You a Leader or a Boss? The Choice is Yours

Are You a Leader or a Boss? The Choice is Yours

Posted on May 14, 2025

Enter your email to receive important news and article updates.