As Scully Signal Co. celebrates its 80th anniversary, it is engaging with customers and investing in engineering to help fuel distributors pursue new opportunities.

Executive Vice President Katrina Scully Ohl, granddaughter of company founder Frank Scully, says the company enjoys plenty of appreciation from its customer base but also faces some struggles. She feels a strong sense of kinship with the fuel oil industry in this regard.

“The whole fuel oil industry seems to be transitioning to the next generation,” she told Oil & Energy. “The sons and daughters and nieces and nephews seem to be taking over, and there is a new way of thinking about things. People had been depressed about the shrinking of the industry, but you see the next generation going into new things like LPG and air conditioning and just helping customers get smarter and more efficient with energy. We think there is a lot of opportunity out there for dealers that are forward thinking and willing to adapt. We can provide them with technologies that will help them out.”

Scully enjoys an iconic status in the fuel oil industry as the creator of the Ventalarm Signal®, which provides the whistle sound during the filling of a home heating oil tank and has inspired the widely used “No whistle, no fill” guideline. “Our name is synonymous with the product,” Ohl said. “We’re like Kleenex.”

Life at the top isn’t always easy, however. Like other creators of industry-standard equipment, Scully has lost market share to knockoff competitors. “Since the beginning, Scully has been focused on innovation, and most of the products we make are original patents of ours,” Ohl explained. “Only after those patents ran out did others come along and copy the products. Our competitors are all basically selling copies of our products, and they even use similar names and typefaces purposefully to confuse people.”

Scully representatives see that confusion in action when they call on petroleum companies. It is not unusual for an owner or top manager to believe their installers or delivery teams are using Scully products when in fact they have been buying knock-offs, according to Frank Scully, Sales & Service Representative for the Northeast region. “A lot of times managers who have good feelings about Scully are unaware of what is going on under them in the company,” he said.

“People think they are getting Scully, but they’re not,” Ohl added. “We are trying to educate people. They think that if it looks the same it works the same. But if the cap cracks or a float is made of plastic instead of cork, it will be a liability for them down the road. We’re not the kind of company that bashes the competition, but at some point you have to educate people.”

New Generation Steps Up

Ohl and Scully are members of the third generation at Scully and are committed to product development and staying in close touch with companies that distribute petroleum products. “The company is investing heavily in engineering and getting out and talking to customers,” Ohl said. Frank Scully added, “We have a lot of people out in the field, and we are getting a lot of feedback.”

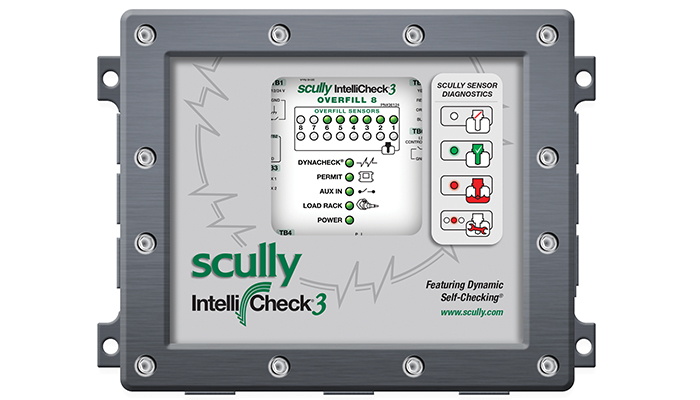

Product innovation is in the company’s DNA, and Scully has been on the leading edge of many important innovations. One important area of continuous activity is overfill protection for terminals and tank trucks. The company recently introduced IntelliCheck3, the third iteration of its sensor-activated system that virtually eliminates the risk of overfills. The systems use an optical or thermistor sensor on the inside top of a cargo or bulk storage tank to detect when the vessel is nearly full and then automatically shut down the fuel dispenser. IntelliCheck3 also provides vehicle grounding at the rack.

Scully manufactures the sensors in a clean room at its Wilmington, MA, plant. Approximately two-thirds of Scully’s manufacturing team work on electronics manufacturing and assembly.

While Scully is not directly involved today in degree-day forecasting or remote tank monitoring, it was once a pioneer of both technologies. Before PCs became popular, Scully developed and ran a mainframe-based degree-day forecasting system for customers. And the first wave of remote tank monitors also came from Scully, but they used landlines and eventually were replaced by monitors relying on cellular phone service and satellite transmission.

The pioneering spirit remains alive, and Scully is keeping an ear to the ground and looking for new opportunities to help fuel companies operate more productively. The company even looks for ways to update the Ventalarm system and Scully’s immensely popular hose nozzles, but the product designs leave scant room for improvement, according to Ohl. The fill whistles often outlast the tanks they are installed on, and there is no worry about changing batteries. “We have looked at going to electronics on the Ventalarm, but that is an example where the simple mechanical solution remains the best,” she said.

Scully will continue to pursue innovation while maintaining its commitments to the family style of business and U.S.-based manufacturing. “Family businesses like working with other family businesses because they appreciate the individual relationships, the focus and the attention to detail,” Ohl said. “They also share a bond of competing against large corporate entities.”