All

Extending the Data Network to the Truck

by John MacKenna

EDITOR’S NOTE: Onboard computing can open a host of business improvements, including reduced delivery costs and enhanced customer service. Oil & Energy recently spoke with ADD Systems about Raven®, the company’s onboard computing solution.

ADD Systems offers fuel retailers the ability to manage and communicate fuel delivery data from the delivery truck to the back office and out to the customer by combining the Raven® mobile platform with other ADD Systems products.

ADD Systems offers fuel retailers the ability to manage and communicate fuel delivery data from the delivery truck to the back office and out to the customer by combining the Raven® mobile platform with other ADD Systems products.

Oil & Energy recently reached out to John Redmond, Vice President of Product Strategy for ADD Systems, for an extended discussion of the Raven platform and the business process improvements that it enables.

ADD Systems has been selling Raven as a unique product since 1997 but offers it only to customers using ADD Systems back office software, such as the ADD Energy E3® system. Raven functions primarily as a data and communications tool for the dispatch and delivery team. It also feeds delivery data to the back office, which can enable numerous process and customer service improvements, depending on what ADD Systems products the company uses.

Handhelds in the Trucks

The key elements of Raven are the handheld computers that drivers carry in the trucks and the software dashboard that dispatchers use to monitor activities in the field. Redmond said that ADD Systems uses handheld computers from Intermec for Raven because they are easy to use and rugged. “Average driver training time is two to three hours,” he said. “Back in the ’90s we used to say it was as simple as using an ATM. Now we say it’s as simple as using a smart phone.”

ADD Systems first created Raven to simplify the delivery driver’s chores, according to Redmond. The first important functionality was to load the pricing and tax rate for each account so that the drivers could pump fuel without manually changing the register settings at each stop. In the intervening years, ADD Systems has expanded Raven’s capabilities to make it a complete dispatch and data management solution.

The newest Intermec device for Raven is the CN70, which ADD Systems began using about 18 months ago. ADD Systems continues to support older versions of the handheld and notifies customers with every software upgrade how the software will perform on each generation of device. Customers are not required to update their devices; rather, they migrate when they want to take advantage of software functions that only the newer devices support.

Redmond explained that the Intermec handhelds ride in a dock in the truck’s cab and are generally hard-wired to the truck’s register. An electronic register is not required, but 95 percent of ADD Systems customers have installed them. With an electronic register, delivery data transfers automatically to the Intermec handheld – and from there to the ADD Systems back office system. With a mechanical register on the truck, the driver must key in the delivery data. To ensure correct delivery on manual entry, the system requires the driver to enter the delivery data twice.

Daily Planner

One of Raven’s core functions is to provide the delivery driver with their routes for the day and all the supporting information they need. Dispatchers can develop routes using the tools in ADD Energy E3 or by using another vendor’s route optimization software. Redmond said the software can divide the day’s deliveries by vehicle and create driver-ready routes, but most dispatchers choose instead to finalize the routes themselves.

One of Raven’s core functions is to provide the delivery driver with their routes for the day and all the supporting information they need. Dispatchers can develop routes using the tools in ADD Energy E3 or by using another vendor’s route optimization software. Redmond said the software can divide the day’s deliveries by vehicle and create driver-ready routes, but most dispatchers choose instead to finalize the routes themselves.

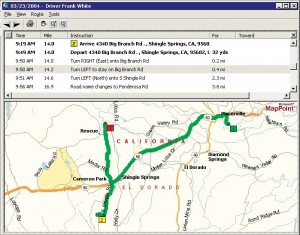

With the routes loaded, the driver’s day is planned, and the handheld can direct them to their stops with the option of turn-by-turn directions that can be verbally provided to the driver. The Intermec device has an internal GPS, and ADD Systems loads it with navigation software called Co-Pilot. The driver simply selects his next stop, presses the navigate button and Co-Pilot guides him there via voice.

When an electronic register is present, the driver is free to focus on driving and pumping fuel, because virtually all other tasks are eliminated. When making a delivery, the driver simply pushes a button to initiate the transaction and then pumps the fuel. Pricing is preloaded, and the system is programmed to print a delivery invoice once the driver finishes pumping.

“The concept is that the driver can pull up to the house, make the delivery, and not be conscious of the customer’s price or pre-buy plan, because Raven knows it all,” Redmond said. “By the time they have rolled up the hose, a customer invoice is printed in the cab.”

“The concept is that the driver can pull up to the house, make the delivery, and not be conscious of the customer’s price or pre-buy plan, because Raven knows it all,” Redmond said. “By the time they have rolled up the hose, a customer invoice is printed in the cab.”

Wireless Capabilities

Perhaps the biggest differentiator in capability with Raven is the choice of whether to go wireless. In the non-wireless configuration, there is no live data transmission from the truck. Instead, delivery data accumulates in the handheld device to be downloaded at the end of the shift, when the driver moves the handheld to a docking station at the office. Delivery information is automatically written to each customer’s account once the handheld is docked.

With a wireless configuration, Raven uses the Intermec handheld’s cellular telephone capabilities to transmit delivery data on the fly while the driver is on the road. If the truck goes out of cellular transmission range, the Intermec device saves and queues the delivery information for transmission once cellular transmission is re-established.

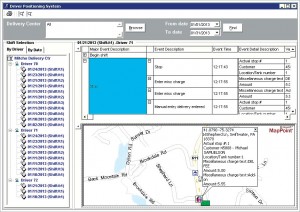

Back at the office, the dispatcher uses the Raven dashboard to monitor activities in the field. If the Raven units are transmitting wirelessly, the basic display includes a column or row of real-time data for each truck, showing how many stops they have made, how much fuel they have pumped, how much fuel is left on the truck and more. A dispatcher can also drill down to the data on each delivery. The dashboard also features a map of the dealer’s delivery area that shows where all the trucks are.

When the Raven handhelds are transmitting wirelessly, a dispatcher can also send messages and data to the handhelds. That includes the option to insert a new stop in a driver’s route on the fly. “The dispatcher can see where the vehicles are and how much product is left, so if an unexpected will-call order comes in, the dispatcher can decide whether to assign the delivery today and which driver to give it to,” Redmond said.

Wireless operations promote efficient dispatch operations, according to Redmond. “Without wireless, when you need to assign a new stop, you probably have to contact each driver via radio or cell phone to find out where they are in their route, and dispatchers can spend a lot of time communicating verbally. But with wireless in place, the dispatcher can focus more on building and implementing the most productive day possible.”

Changing With the Times

Redmond said wireless transmission is gaining popularity. “We’ve seen the popularity of wireless go up dramatically. Five years ago, about 10 to 15 percent of our customers used wireless. Now it’s about 40 percent,” he said. The popularity of smart phones has raised awareness of wireless capabilities and changed the expectations of both companies and their customers.

The heating oil and propane markets are shifting, with degree-day-based automatic deliveries being replaced by will-calls, and the wireless Raven environment is highly supportive of will-calls because of the scheduling flexibility, according to Redmond. When an ADD Systems client is trying to choose between wireless and non-wireless, he asks them what percent of their business is will-call, because a company that does mostly automatic delivery has less need for wireless.

Wireless is also great for customer service, because delivery information is delivered in near real time to the back office system that is accessed by customer service representatives (CSRs). If a customer is nervous about their delivery and calls the office, the CSRs will be able to confirm delivery within moments, Redmond said.

Businesses that use ADD Systems can also purchase SmartConnect® modules that enable a software developer to build a customer account lookup section on their website where customers can view their account data. With Raven running wirelessly, delivery information can flow to the customer portal in near real time.

Redmond said there is a growing segment of the heating oil and propane market that is looking for companies with strong self-service features, because they want to do business by the Internet or text. “Wireless meshes well with customer expectations and aligns with the self-service mindset of people who don’t want to deal with companies on the phone,” he added. “The younger generation can come to your website and tell right away whether they want to do business with you.”

Companies are seeing the writing on the wall and gravitating to wireless on the truck side and customer self-service on the web side, according to Redmond. “If you don’t do it, your competition will,” he said.

Cost Buster

In addition to the customer service benefits, wireless Raven can also help reduce costs. He has watched several companies with multiple locations use the capabilities of Raven to help reduce dispatching costs. “With wireless capability, Raven is seen as an enabling technology for companies considering consolidation of dispatch and reduction of driving costs,” Redmond said.

When dispatch has the capability to track all trucks, monitor their progress on deliveries and assign new stops on the fly, there is no need to maintain multiple dispatch operations, even when a company has an expansive delivery area, he said.

As dispatch becomes more technology intensive, the ideal profile of the dispatcher is changing. In the past many companies have rewarded a top driver by moving him inside to dispatch. In a wireless environment, companies put a high priority on the dispatcher’s comfort level with computers and technology, Redmond said.

Protecting the Company

Raven can also help companies manage drivers more effectively, because it provides hard facts about their performance. “You have a much clearer picture of what the driver is doing,” Redmond said. “Raven winds up telling you what you already knew, and now you have the evidence.” Companies that use ADD Systems’ Atlas Business Intelligence™ software can also benchmark driver performance against industry standards.

ADD Systems customers can also use Raven’s GPS capabilities to ensure that deliveries are made to the correct location. “When you make your first delivery using GPS, Raven actually stamps where the truck was physically located, so you capture the latitude and longitude of where the truck was located. Next time you go back, Raven compares where the truck is now to where it was last time. If you are outside the user-defined parameters, Raven warns the driver that he is not at the right location,” Redmond explained.

ADD Systems can also set up the onboard registers to time out shortly after the driver stops pumping. This option provides theft prevention, because the driver does not have the option to leave the ticket open and pump fuel someplace else, such as into a friend’s tank.

Related Posts

Optimizing Operations

Optimizing Operations

Posted on February 12, 2024

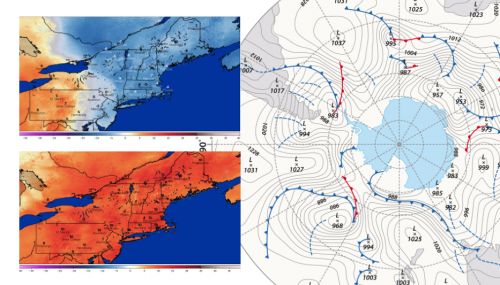

National Weather Forecasting Takes NEFI by Storm

National Weather Forecasting Takes NEFI by Storm

Posted on December 8, 2023

A Chance Hydrogen Discovery

A Chance Hydrogen Discovery

Posted on December 7, 2023

Winter 2023-2024 First Impressions

Winter 2023-2024 First Impressions

Posted on October 11, 2023

Enter your email to receive important news and article updates.