It may be time to change your old way of doing things, even after 100 years of use

“I know how to install a regulator,” you insist. Regulators to control the pressure of propane vapor systems have been around since the commercialization of propane for consumer use. Not a lot has changed regarding how they are installed in more than 100 years.

In a two-stage propane regulator system, second-stage regulators are installed at the building. Regulator installation best practices require positioning regulators with the vent opening aligned horizontally with the ground to prevent the potential buildup of moisture in the regulator. To achieve this, one can position the regulator with the inlet (and thus the regulator vent) pointing downward, or use any number of vent adapters available to reposition the vent, or (as common practice years ago) unscrew the top half of the regulator and turn it to point the regulator vent downward. The last option is frowned upon today, and in most cases prohibited.

Many installers will also put the second-stage regulator under a cover. However, it is still good practice to point the regulator vent down even with a cover. Most service technicians have gone to a customer location and said, “I wonder what happened to that second-stage regulator cover?” at one time or another. There are second-stage regulators that are manufactured with vent-in alternate positions, but most service technicians do not want to carry that much inventory on their trucks.

When first-stage regulators are installed at a propane tank under the tank dome, an estimated 90 percent or more of the installations end with the bottom side of the regulator positioned toward the tank. This results in the top half of the regulator (the adjustment-cap, or atmospheric side) pointing upward. In an effort to prevent the regulator from accumulating any moisture inside, the installer typically tilts the regulator outlet in a slightly downward position. At this point, most folks that have installed a regulator are nodding their heads agreeing with what they have just read.

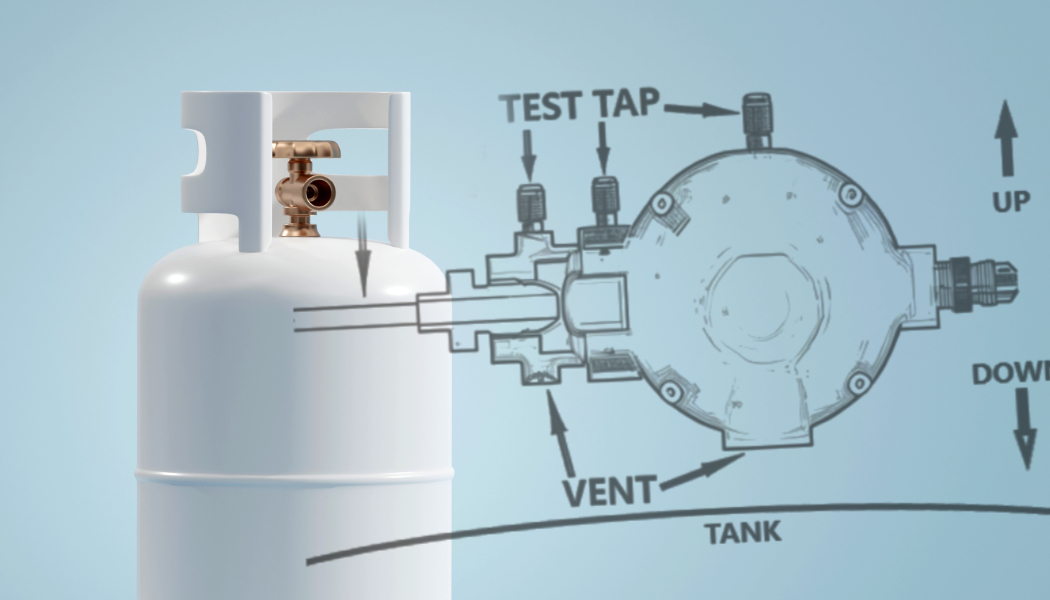

There is a much more effective way to install a first-stage regulator on a propane tank, however. Most manufacturers make regulators with vents in a downward position and the regulator test taps positioned upward (see accompanying image). This is typically referred to as “tap over vent”. Tap-over-vent regulators have been available for the past 20 years or so.

It comes as no surprise that human nature makes most of us very set in our ways. Change is often met with resistance. Propane service technicians are no different. Why would a service technician want to change the regulator configurations they have always used? They know the item part numbers and their preferred installation method has always seemed to work. In fact, many tap-over-vent regulator (perhaps when ordered by mistake) installations are positioned the way many non-tap-over-vent installations are done.

So why should installers use tap-over-vent first-stage regulators? First, when installed as shown in the image, the pigtail can slope back toward the service valve, thus reducing the chance of debris or moisture accumulating at the inlet orifice. Many service technicians will say they already do that. But, if the first-stage regulator is positioned with the vent slightly downward as most installers typically do, the inlet of the regulator is then pointing slightly upward creating a “trap” at the inlet. The tap-over-valve regulator configuration allows the inlet of the first-stage regulator to tilt back toward the service valve. This should prevent moisture and debris from accumulating at the regulator orifice, flowing back through the pigtail to the tank instead. The regulator vent still points downward, allowing any moisture to drain out the vent. Plus, as an added bonus, the test taps are pointing outward, allowing an easier connection for pressure testing. Tap-over-vent regulator installations also seem to take up less space under the tank dome, allowing easier access to the fill valve, fixed liquid level valve, and float gauge dial.

Tap-over-vent regulators really are a no-brainer. When properly explained, tap-over-vent first-stage regulators would seem to be a more popular regulator configuration option than standard configurations. Ask your propane equipment distributor to explain the benefits of proper tap-over-vent first-stage regulator installations during your next safety meeting. It is important to note that the tap-over-vent design is the same for twin-stage regulators – which is commonly used in the northeast U.S. Even a seasoned service technician has to admit, “huh, I never thought about that!” after learning the many benefits of tap-over-vent first-stage, or twin-stage, propane regulators.

Scott Gaudet is the Area Sales Manager for Bergquist covering the Northeast. He has almost 4 decades of experience in the propane industry. He can be reached at scott.gaudet@bergquistinc.com.