Companies that sell energy products and comfort services can leverage technological solutions to derive greater value from their assets, according to a technology executive who is focused on the retail energy industry.

Aaron Cargas, Vice President of Marketing and Product Development at Cargas Systems, works with energy marketers who use Cargas Energy back-office software. He recently spoke with Oil & Energy about how energy companies can optimize operations by centralizing and extending data-driven communications.

“An energy company—when you boil down what is does on a day-to-day basis—has expensive rolling assets on the road in its fuel trucks and service vans,” he said. “Our focus is on maximizing the use of those assets and getting the best return out of them. When you are delivering fuel, you are trying to minimize the time that the driver needs to spend on things that don’t produce revenue. You have the costs in place, and the goal is to deliver more with the same assets.

“We’ve had customers tell us they delivered more gallons the next year with fewer trucks on the road. They increased the top line and reduced costs at the same time by becoming more optimized.”

Opportunities in Real Time

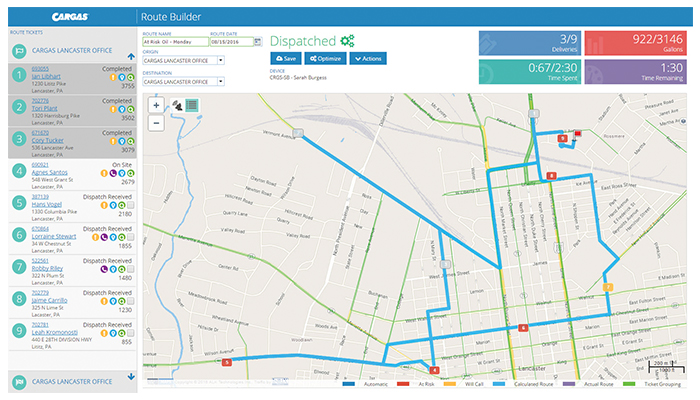

Software and hardware systems have come a long way and are now integral to improving a company’s return on assets, according to Cargas. Energy companies had originally used computers merely to replace paper-based record keeping, and they entered data after completing a delivery to facilitate billing and accounting. “Today, our system has evolved into a real-time communications hub that works during the day to inform users in real time, and that information helps you optimize the use of your assets during the workday, especially on busy days,” he explained.

Mobile applications that incorporate location data and report in real time have become highly proficient and reliable, particularly with the spread of the high-speed 4G mobile communications standard. Now each vehicle can carry a tablet computer that enables two-way, real-time communications with the back office software, and drivers can be freed from a morning ritual of sorting tickets and preparing routes. Routes can be auto-loaded and updated during the day to accommodate unpredictable changes, such as rush will-call deliveries.

“The ability to have a real-time communications hub allows you to optimize fuel delivery,” Cargas said. Dispatch receives rich data on vehicles in real time that can help them make better decisions based on where the trucks are located at any given time and how much fuel they are carrying.

Technology can also boost efficiency in the back office. “With data flowing quickly from the trucks, posting is faster, end-of month reports are faster, and billing is faster,” he said. Up-to-date technology reduces data entry and other redundant work and enables the company to redeploy people to be more focused on serving customers and developing new business proactively. “You can right-size the number of people you have doing process work and focus the others on providing better customer service,” he added.

Another technological advancement that creates cost control opportunities is the increasing use of web-based software that operates through a browser on different devices, without the need for specialized client software. “It can create a centralized system that people can securely log into from remote locations,” Cargas explained. “They see what they need to see, and they can share as needed and even have one location take over operations for another.” web-based software is particularly helpful in an acquisition, because a company can bring a new location onboard without having to install software there.

Extending the Sphere

Advanced energy marketing software can also interact with other technologies to improve business processes. Cargas said more companies are using tank monitors, and the monitor vendors are working with software providers to make the best use of the data they generate. Cargas Energy can now integrate tank monitor data seamlessly into delivery dispatching operations, so companies can place monitors on locations that have erratic usage and work them automatically into the delivery schedule, even on short notice. “The cost to deploy monitors is coming down, and you can save on delivery costs, because you get more accurate data and can deliver more optimally with larger drop sizes,” Cargas said.

Forecasting software can also help companies accelerate certain deliveries selectively so they can spread out their delivery schedules and achieve better use of delivery assets and avoid overtime and other cost spikes when cold weather arrives, according to Cargas.

Automation can also help service departments reduce inventory costs. Companies can sign up for automated parts reordering with a wholesaler and use a system such as Cargas Energy to track inventory and automatically generate orders, so they can have less cash tied up in spare parts. Service departments can also streamline the billing process by using mobile devices that enable them to generate invoices and capture signatures at the customer’s location.